Wholesale Biodegradable Pouches

Customized Designs, Size, Add-ons | MOQ 10,000pcs

- More than 20 years’ design & manufacturing experiences on Flexible Packaging

- MOQ lower to 1,000 Pcs per design, shortest delivery in 3 weeks

- High barrier property materials

- By Kraft, PLA, PBS, etc

- Eye-catching and premium quality printing up to 8 colors

- Free coffee pouch samples for quality reference

- Fastest quotation for custom printing pouches within 24 hours

- Come in a wide variety of shapes, styles, colors, and materials.

- There are many different biodegradable bags & pouches recommended for food packaging: Stand up pouches with or without zipper/valves/windows; Side gusseted bags; Flat bottom pouches; Tin-tie pouches, etc.

We Produce Various Types of Wholesale Biodegradable Bags & Pouches

Biodegradable pouch packaging is made from plant-based, recycled materials. This means packaging can break down and be disposed of in a way that is far kinder to the environment than plastic.

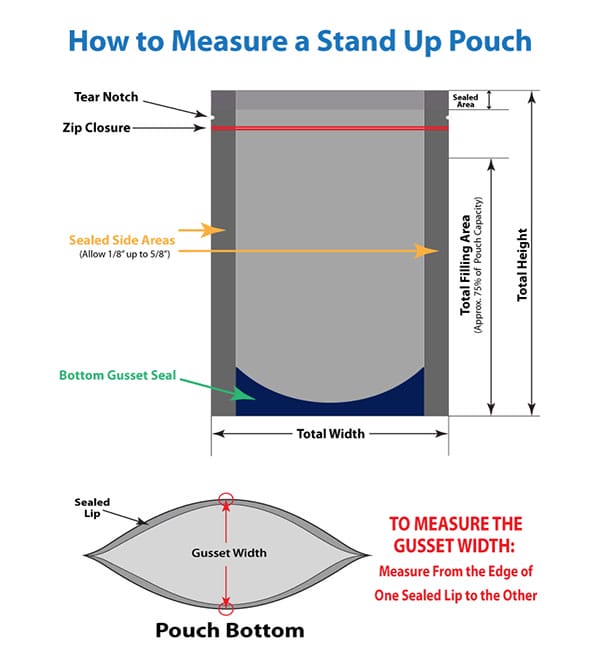

Biodegradable Bags Size Charts for Reference only

It’s totally customized; you could have your own unique packaging, with custom size, shape, printing, features.

| MOQ | 10k-20k per SKU |

| Volume | 2oz, 1oz, 2oz, 4oz, 8oz, 12oz, 16oz, 24oz,32oz, 1lb, 2lbs, 3lbs, 4lbs, 5lbs |

| Materials | Kraft Paper / PLA / PBS / NK / NKME |

| Thickness | 2.5Mil-8Mil (70Mircons-200Mircons) |

| Add-on Features | Punching Hole, Euro hole, Handle, Ziplock, Valve, Window, Tear Notch, Round Corner |

| Appearance | Custom Design Printing, UV Logo, Stamping, Matt Surface, Glossy Surface |

| Leadtime | Cargo to be ready 10-20 days after order |

| Terms of Payment | Wire Transfer (T/T) / Paypal / Western Union |

| Volume (gram) | Volume (oz) | Width (mm) | Width (inch) | Length (mm) | Length (inch) | Gusset (mm) | Gusset (inch) |

|---|---|---|---|---|---|---|---|

| 28 | 1 | 80 | 3.15 | 130 | 5.11 | 40 | 1.60 |

| 70 | 2 | 110 | 4.35 | 160 | 6.30 | 60 | 2.35 |

| 100 | 3 | 120 | 4.75 | 200 | 7.90 | 60 | 2.35 |

| 150 | 4 | 130 | 5.10 | 210 | 8.25 | 60 | 2.35 |

| 250 | 8 | 160 | 6.30 | 230 | 9.05 | 70 | 2.75 |

| 500 | 16 | 190 | 7.50 | 265 | 10.20 | 90 | 3.55 |

| 1000 | 32 | 240 | 9.25 | 335 | 13.20 | 100 | 4.00 |

| 3000 | 106 | 300 | 11.8 | 500 | 17.90 | 70 | 2.75 |

| 4000 | 141 | 380 | 14.9 | 550 | 21.60 | 80 | 3.15 |

| Volume (MT) | Volume (EN) | Width (mm) | Width (inch) | Length (mm) | Length (inch) | Gusset (mm) | Gusset (inch) |

|---|---|---|---|---|---|---|---|

| 100 gs | 4 oz | 90 | 3 5/9 | 185 | 7 7/25 | 55 | 2 1/6 |

| 250 gs | 8 oz | 95 | 3 5/7 | 238 | 9 | 70 | 2 5/7 |

| 340 gs | 12 oz | 127 | 5 | 200 | 8 | 80 | 3 1/8 |

| 500 gs | 16 oz | 112 | 4 3/8 | 280 | 10 7/8 | 80 | 3 1/8 |

| 1000 gs | 2.2 lbs | 146 | 5 3/4 | 343 | 13 1/2 | 102 | 4 |

| 1180 gs | 2.6 lbs | 150 | 5 3/4 | 330 | 13 | 118 | 4 5/8 |

| Volume (Mt) | Volume (En) | Width (mm) | Width (inch) | Length (mm) | Length (inch) | Gusset (mm) | Gusset (inch) |

|---|---|---|---|---|---|---|---|

| 60 gs | 2 oz | 51 | 2 | 190 | 7 1/2 | 32 | 1 1/4 |

| 100 gs | 4 oz | 68 | 2 2/3 | 226 | 8 7/8 | 42 | 1 5/8 |

| 250 gs | 8 oz | 90 | 3 1/2 | 260 | 10 1/4 | 70 | 2 3/4 |

| 500 gs | 16 oz | 96 | 3 3/4 | 330 | 13 | 77 | 3 |

| 1 kgs | 2 lbs | 136 | 5 1/3 | 420 | 16 1/2 | 77 | 3 |

| 1.4 kgs | 3 lbs | 140 | 5 1/2 | 445 | 17 1/2 | 80 | 3 1/8 |

| 2.2 kgs | 5 lbs | 178 | 7 | 490 | 19 1/4 | 115 | 4 1/2 |

| 5 kgs | 10 lbs | 280 | 11 | 623 | 24 1/2 | 130 | 5 1/8 |

| 10 kgs | 20 lbs | 356 | 14 | 715 | 28 1/8 | 80 | 3 1/8 |

| 20 kgs | 40 lbs | 408 | 16 | 820 | 32 1/4 | 140 | 5 1/2 |

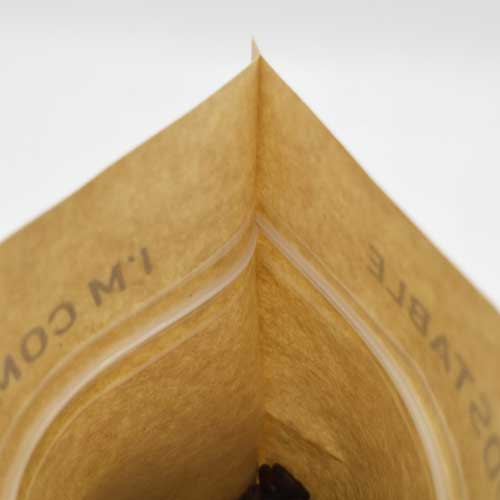

Biodegradable Side Gusset Pouch

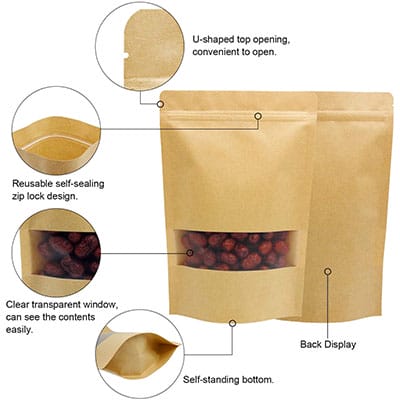

Biodegradable Kraft Stand Up Pouch

Biodegradable kraft stand up pouch mainly refer to the food and non food packaging with multi-layer structure. It covers the bag types of stand up bags, doypack bags, flat bottom bags, quad seal bags.

The kraft layer is normally the external layer or the 2nd layer with a transparent film outside. Eco protection policies in more countries make it necessary to reduce the usage of plastic in packaging pouches.

Another kind of kraft packing bag is the kraft SOS bag, with a flat bottom. It goes with kraft only, without any other layer, always sealed by a tin tie.

Matt Biodegradable pouch

It brings your food the best and thoroughly protection. The food pouch volumes vary from 2 oz to 15 lbs.

Matt food bags could be custom with branded designs, printed labels, improving the promotion of your products

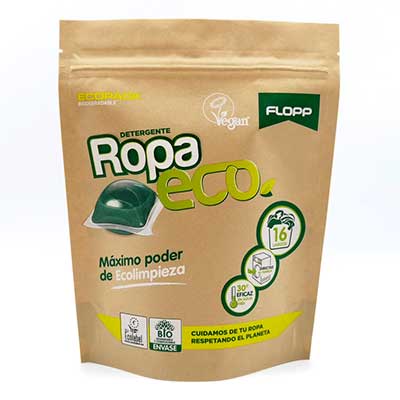

Custom Printed Biodegradable pouch

Ground coffee bags will go with vents as well. It should be with a filter. For a coffee bean bag, it may go with valves without a filter.

Besides valves, zip locks, tear notches, round corners, pocket zip locks, custom design printing are also available.

Biodegradable Food Pouch with Ziplock

The black image always has a noble temperament. The black design will always help to improve the brand style.

Food pouches go with a one-way degassing valve to let carbon gas exit the bag and preventing air from getting into your bag meanwhile. The current flexible packaging preserves the freshness and flavor. The black bags are available in various sizes and custom printing, meeting your packaging needs and promotion demands.

Biodegradable Kraft Flat Bottom Pouch

Degassing vents are also available for kraft paper coffee bags. The one-way valve is used to expel gas released by roasted coffee beans. The carbon gas accumulates inside the coffee bags. The vents help to discharge the gas, meanwhile preventing the air outside coming inwards.

Biodegradable Stand Up Pouch w/ window

A regular type of stand-up pouch is known as doypack. In fact, box bottom pouches, side gusset bags are also self-standing bags. It’s based on different promotion purposes and packaging demands.

The main feature of stand-up pouch is composite film structure, combining all characteristics of different materials. A final and qualified food packaging must go with one-way degassing vents, resealable closure (ziplock, tin tie), look-through windows, tear notches, etc.

Biodegradable Pouch with Venting Valve

The bags will be applied with degassing valves, expelling gas inside out one-way only. Resealable ziplock is still available for this kind of bag. Other extra features include look-through windows, tear notches, round corners, curved bottoms, etc.

Kraft paper side gusset biodegradable bag

It will offer thorough protection to your product with a high barrier multi-layer composite structure, against UV rays, moisture, oxygen, pets. The packaging keeps the content fresh and flavors.

The films used for food bags are all with FDA certificates, and BPA free.

The Completely FAQ Guide to Biodegradable Bags

Chapter 1: Definition of Biodegradable Bag

Chapter 2: Usages of Biodegradable Bags

Chapter 3: Add-ons Features

Chapter 4: Types of Biodegradable Pouch

Chapter 5: Biodegradable Pouches Materials Guide

Chapter 6: Biodegradable Bags Manufacturing Guide

Chapter 7: Biodegradable Pouches Testing

Chapter 8: Warehousing and Storage

Chapter 9: Biodegradable Pouch Frequently Asked Questions (FAQ)

Chapter 10: Packing, Filling, and Sealing

Chapter 11: OUMA Biodegradable Pouch Packaging Pouches

Chapter 1: Definition of Biodegradable Pouch

Biodegradable packaging, some also called Compostable packaging, is made, disposed of and breaks down in a manner that is kinder to the environment than plastic. It is made from plant-based, recycled materials and can return to earth quickly and safely as soil when disposed of in the right environmental conditions.

The major benefits to the environment are that Biodegradable packaging requires less carbon to produce, reduces the amount of waste sent to landfill and provides the earth with life-promoting nutrients.

Such eco-friendly flexible packaging is the future of packaging way. More an more countries carry out green packaging policy.

Compostable products are defined as biodegradable and non-toxic. They break down into water, biomass, and carbon dioxide within 90 to 180 days of disposal. In addition to their ability to completely break down, they also disintegrate into the compost with nothing left behind.

So, not only is composting safer to human and environmental health, but it basically leaves behind no negative effects whatsoever.

Biodegradable bags are widely used for the packaging of food, coffee, tea, snacks, candy, garments, and digital accessories.

The factors to consider when choosing biodegradable bags

There are upto 10 kinds of different materials available for sustainable biodegradable packaging pouches. Which is suitable for your demand? The packaging purpose is one of the main factor. Strength, costs, quality are all we need to consider. Pls contact Ouma for the best solutions!

Chapter 2: Usages of Biodegradable Pouches

Ouma Biodegradable pouches are widely used for the packaging of food, snack, coffee, tea, cosmetics and personal hygiene, pharmaceutical and medical products, nutritional supplement and health food, and industrial & non-food items.

Biodegradable coffee bag is one of the main usage. Coffee is a brewed drink prepared from roasted coffee beans, the seeds of berries from certain Coffee species. Coffee goes in different form, roasted coffee beans, ground coffee, or liquid.

Our Biodegradable Pouches Cover A Wide Range of Applications

Coffee Bags for Roasted Coffee Beans

Custom biodegradable coffee bags are available for roasted coffee beans, in all kinds of pouch types, specification, and printing. The coffee bag we manufacture is suitable for both roasted coffee beans and ground coffee, with multi-layer high barrier structures by lamination.

Add-ons like ziplock, valves, hanging holes, are available for all our well laminated coffee packaging pouches, to help you maintain coffee flavor, freshness, expanding the product shelf life.

Biodegradable Food Packaging Pouches

Ouma packaging bags are designed mainly for food packaging, like nuts, jerky, snacks, candy, chocolates, etc. They are featured with high barrier laminated films, valves, ziplock, etc.

We produce stand-up pouches, side gusset bags, 3-side seal bags, pillow bags (fin seal pouches).

Biodegradable Pet Food Pouches

Pet food packaging, and pet care products packaging is another main market. Ouma packaging bags are designed for dog, cat, fish, bird and other pet food packaging. They are featured with high barrier laminated films, valves, ziplock, etc.

We produce stand-up pouches, side gusset bags, 3-side seal bags, pillow bags (fin seal pouches).

Chapter 3: Biodegradable Pouch Add-ons

By applying with different add-ons, compostable bags can bring the consumers great convenience, and happiness.

Various accessories will be applied to our eco-friendly packaging, which will make it easier for customers and retailers when opening, packing, resealing the contents.

It’s fully customized to use what kinds of add-ons for your biodegradable bags. Or just reach us, we will offer you the best proposals, based on your market demands.

Chapter 3.1: One-Way Degassing Valves of coffee bags

Originally developed for coffee and now utilized widely by other markets, one-way degassing valve allows carbon dioxide to escape from a package without allowing oxygen or moisture in. This cleverly engineered 5-piece valve, about the size of a button, brings with it a host of benefits that include:

- Longer product shelf life

- Preservation of product quality, taste and freshness

- Compact, stable palletization for storage and transportation savings and ease

- Opening and closing pressures that ensure consistent, leak-proof operation without package over-inflation

- Durable design built not to bend, crack or flex under normal use and to withstand thousands of openings and closings

- Unique valve caps that are mechanically locked into bases to protect internal valve parts from damage and prevent debris from entering the valve

- Facilitation of steam release during microwaving

There will be about 7 days that the roasted coffee gives away gas like Co2. If you pack up the coffee during this period with a pouch without degassing valve, the pouch may get burst sometimes.

Here are some of the valve types we have ever used:

Chapter3.1.1: WIPF Degassing Valves

This is one of the World’s Most Reliable Degassing Valve.

It takes sophisticated technical solutions to protect food products, espe-cially those that remain active in their packaging.

WICOVALVE® aroma-protec-tion/pressure-relief was originally designed for coffee. During the past years, this valve technology has been refined and modified for many new applications.

Chapter3.1.2: Goglio Valves

The one-way degassing valve, originally invented and developed by Goglio, has given an important contribution to the development of flexible packaging. Itis produced using raw materials approved by European authorities, the FDA and the Japanese Ministry of Health.

Chapter 3.2: Resealable Ziplocks

Resealable bags are those with a pressure sensitive or side-seal closure. These bags are used everywhere.

Whether you are manufacturing, processing and storing food, retailing items of any size or serving the healthcare needs of patients in hospitals, medical and dental offices, pharmacies, home health care or pharmaceutical production, you almost certainly have these bags on hand.

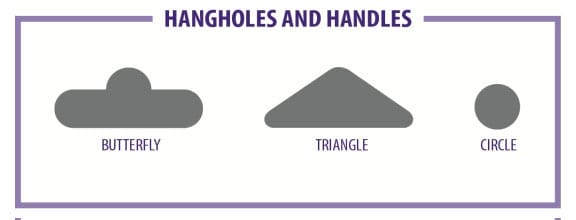

Chapter 3.3: Butterfly Hole (Euro) / Triangle Hole / Round Punch Holes

Hanging on the shelf is another way of displaying your products on the supermarket, besides standing up on the shelf.

To meet different demands, we offer different options of 3 types of hanging holes: Butterfly (also called Euro) hole / Triangle hole / Round hole. These holes will be done by punching tooling. The sizes of holes are customized as well.

With our options, it brings you great convenience when displaying your products. With more 20 years’ experiences, we are sure know how to make it safe and not tearing off when hanging.

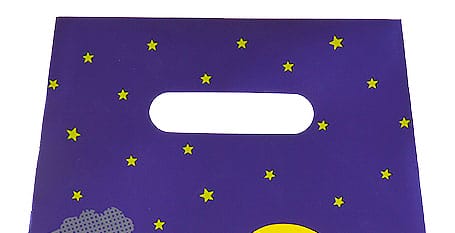

Chapter 3.4: Die-cut handles

Die-cut handles are normally used for pouches with big volume, like spout pouches, dog food bags, pet food bags, merchandise bags. A plastic handle grip will be use for such handles. It will make it easier and convenient for the consumers when they have to take lots of items after shopping.

Chapter 3.5: Ergonomic handles

Ergonomic handles are designed for gift bags, merchandize bags, shopping bags, which are with small loading volume. It’s done by punching with a die-cut tooling, and will not add any extra grip. So it’s not for big loaded pouches.

Chapter 3.6: Rounded Corners

The bigger pouches, the thicker materials. The thick materials make the pouch strong and stiff enough, but it goes with sharp corners as well.

To avoid any unexpected injuries, we offer the options of rounded corner coffee bags. This will make it safe for all consumers, no matter adults, aged or children.

Chapter 3.7: Tear Notches

The start for the consumer to use or consume your product is Opening the pouches, easily, without any tools. This is one of the most important factors for a succeed brand.

So we will add tear notches to most of flexible packaging bags, to increase customer convenience.

Chapter 3.8: Pouch surface finishing: Glossy / Matt

Pouches surface finishing is one of the key issues for packaging design. Glossy finishing makes the biodegradable bags shining or luminous. Matt surface gives biodegradable pouches dull looking.

To have glossy finishing, just make PET as the external layer of pouch lamination structure. For matt finishing, 2 options are available: one is by Matt BOPP film, the other is to put matt vanish on PET. Matt BOPP is the most popular and regular option.

PET and Matt BOPP costs all most the same. It takes more costs with matt vanish, cause the matt vanish will be done by printing plate, which is with the same process as pattern printing.

Chapter 3.9: Look-through windows

Before opening the biodegradable pouches, you could not touch or smell the content inside. But the experienced consumer can tell the quality of content by seeing.

So a look-though clear window is very important. It’s not difficult to keep some part of the pouch transparent. You can even customize the shape of the window, round, oval or unique shapes.

With look-through windows, it will help to improve the sale of your products.

Round Shape

Stripe Shape

Unique Shape

Chapter 3.10: Tin Tie Closures

Compostable bags with ziplocks enable re-opening and re-closing. What if for a flexible pouch without the ziplock? Tin tie closure will take over the function.

It’s available for some different pouches, not only bottom gusset stand up pouches, also for side gusset bags, flat bottom pouches, kraft paper SOS bags, etc.

With a tin tie closure, it will help to avoid the contamination of the content. And it makes it easier to store the food when it is not finish at one serve.

Chapter 3.11: Laser Scoring

Even with a tear notch, it is not so easy to open the pouch if the laminated material is very thick. A laser scoring line can settle this problem with a tear notch. This will help to improve the User Experience.

But only flaw is that it costs quite a lot to have your own laser scoring machine.

Chapter 3.12: Dotted Tear Line

Even with a tear notch, it is not so easy to open the pouch if the laminated material is very thick. A laser scoring line can settle this problem with a tear notch. This will help to improve the User Experience.

But only flaw is that it costs quite a lot to have your own laser scoring machine.

Chapter 3.13: Pocket Ziplocks

Pocket ziplock is a special ziplock which has a tear tab on the pouch body. it’s very easy to open it with the tear tab. Then the biodegradable packaging can be reseal with the ziplock.

The pocket ziplock costs more than the regular ziplock. Packaging Bags with zipper pocket are tamper-evident and designed to ensure safe entrapping of coffee and other foods.

Pocket ziplocks are used for stand up pouches and flat bottom pouches (box pouches).

Chapter 3.14: Curved Bottoms

If for a large stand up pouches, or a stand up pouch used for heavy loading, to assure it will stand straight enough, we can add a curved bottom to the pouches. When it is inflated, the curved bottom make it stand still.

But it takes extra cost for it, cause it requires a tooling for cutting the bottom edge. What’s more, the lead time for curved bottom pouches will be longer than regular pouches, because it will have to be produced on some special machines.

Chapter 3.15: Pouch Bottom Types

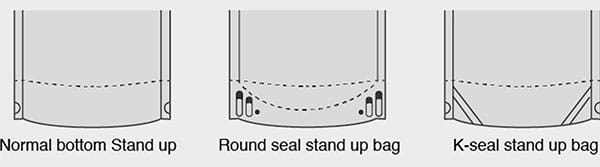

There are 3 different bottom gusset type for stand up pouches: Normal bottom / Round Seal Bottom / K-Seal Bottom. The first 2 types are the most common pouch bottom types.

Chapter 4: Types of Biodegradable Bags

Biodegradable pouches can be made from a variety of substances which include paper, PLA, PBS, NK, etc. It will be converted into many different pouch types, according to the packaging and promotion demands.

Chapter 4.1: Biodegradable Stand up Pouch

Stand-up Biodegradable pouches are one of the most popular packing pouch types. It is also known as standing Bags or Doypack. These are Biodegradable pouch with a bottom gusset that enable them to stand up on the shelf.

Our Stand Up Pouch offers a combination of design and quality to provide you with a professional self-standing packaging solution. Made with a bottom gusset, giving it self-standing strength, it is ideal for shops and general display needs in the retail market. Combine this with an optional Zipper and one-way degassing valve for one of the most effective flexible packaging solutions.

Our self standing pouches are made from the best barrier materials, giving your products superior shelf life, or they can be made clear with excellent visibility of the product inside. For a more natural look, a natural Kraft version is available. If necessary, we can also supply this version with a custom-cut window for even greater product exposure.

Chapter 4.1.1: Kraft Paper Stand Up Pouch Coffee Bags

Nowadays, many countries put in to effect the policy of Prohibition to plastics. So kraft packaging bags are increasing in the usage. But kraft paper can not act in all conditions. So, an alternative is to reduce the usage of plastic.

That’s why kraft + Biodegradable plastic laminated packaging (PLA) are getting more and more popular. Kraft Stand Up Pouches offer a moderate barrier, and are ideal for retailing non-refrigerated products. The inner lamination keeps the products fresh.The bottom gusset pouch design enables the product to stand by itself when full!

There are 3 different kinds of kraft papers biodegradable pouches available for flexible packaging as follows:

Brown (Natural) Kraft Paper Doypack

White Kraft Paper Doypack

Printed Kraft Pouch

Chapter 4.1.2: Biodegradable Stand Up Pouch (Plastics only)

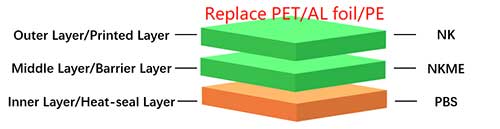

Some products need the packaging with bio-plastic materials only, without kraft paper insdie the lamination. Then we can go with the structure of NK//PBS. NK is one of biodegradable films with the feature of high barrier to water vapor, moisture, oxygen. If it needs to prevent UV lights, NKME will be added in as the middle layer.

Printing on kraft paper is only with max 4 colors. But with bio-plastic structure above, it’s available with printing of upto 8 colors. This composit structure has wider application on flexible packaging.

Printing design, dimensions are all fully customized on all biodegradable bags.

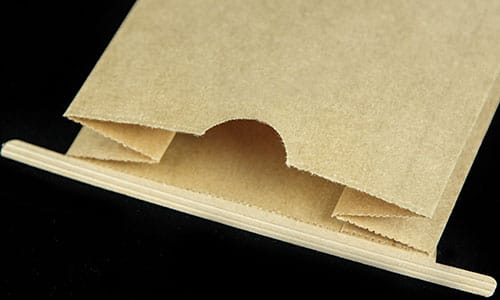

Chapter 4.2: Side Gusset Biodegradable Bags

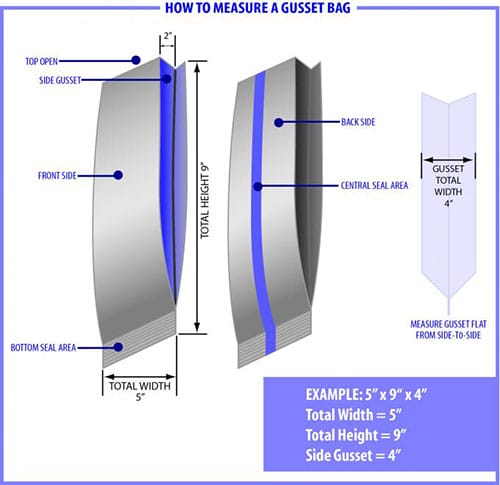

Biodegradable Side gusseted bags are named for the gussets, or folds, on each side of the bag. The gussets expand when the package is filled with products, and the weight of the product usually holds the bag upright.

This package format has two long faces, or panels, on the front and the back for product brand promotion. The side gusset bag is the recognized format for coffee and many food packaging today. It is also widely used in other markets such as, jelly, rice, pet food, powders goods, teas and other specialty food products.

Biodegradable Side gusset bags have transformed the packaging way, making it faster, easier, less expensive. What’s more, there are many add-ons to add to the bags, upgrading the function.

- Best for branding promotion with 4 large panels for printing

- Efficient filling capacity with well opening top ends

- Flexibility due to customization of different sizes

- Excellent barriers with laminated material films

Chapter 4.2.1: Kraft Side Gusset Biodegradable Bags

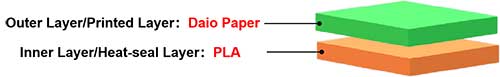

Kraft side gusset bags are one of the most popular food bags packaging way. It’s not simply done by kraft paper, but by multi-layer lamination, for example, Kraft + PLA.

For roasted coffee beans & ground coffee, and some other foods, degassing valves are necessary for the coffee bags, not only side gusset bags, but also stand up pouches and flat bottom pouches.

Chapter 4.2.2: Fully Custom Printed Side Gusset Biodegradable Bags

Design printing on the packaging is very important for all coffee brands’ promotion. The consumers learn everything about your products from the printing details on the packaging bags.

To become eye-catching, and stand out from the shelf with dozens of coffee from different brands, a unique, special packaging design is the key factor. Of cause, a good manufacturer to bring your design to reality is equally important.

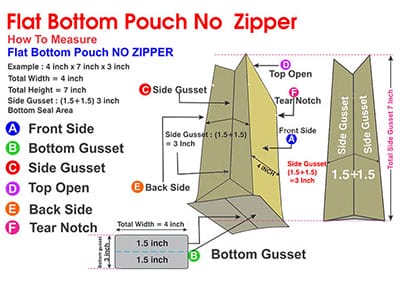

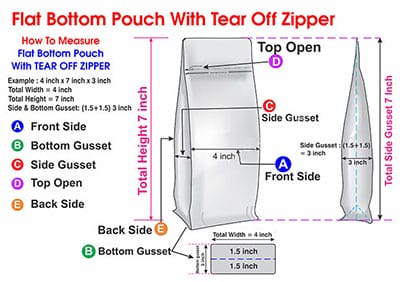

Chapter 4.3: Biodegradable Flat Bottom Pouch

Flat bottom pouches, also known as biodegradable block bottom pouches, box pouches, are the superior type of food and snack packaging pouches. The production of flat bottom pouches is a little more complicated, compare to that of stand up pouches.

The box pouch is with a flat bottom, and both side gussets. It can expand and stand still even before filling. This block bottom pouch is designed to hold the load of 6oz to 20 lbs, various to different materials we use.

Flat bottom food bags offer more space for printing, compared to stand up pouches. All the add-ons are available for flat bottom packaging bags, like look through window, matt finishing, degassing valves, hanging holes and rounded corners, etc.

Chapter 4.3.1: Bio-Plastic Flat Bottom Pouches

Go with the best of both worlds with our new foil flat Bottom Bags with ziplock! Combining the advantages of the traditional side gusseted bag along with those of a stand-up pouch makes these a great fit for any product! The flat bottom allows even the lowest density product to sit securely on the shelves without any worrying about falling over.

The paneled look of these bags makes them perfect for graphics, labeling, and hot stamping as well as degassing valve application. Matte and glossy options are available to suit various brand-promotion needs.

Chapter 4.3.2: Biodegradable Kraft flat bottom Pouches

Protecting the environment against pollution now has become the consensus of all countries in the world. Many traditional plastic materials are not totally eco-friendly types. But kraft paper is recyclable material. So it is a good option to make kraft as the outside layer, reducing the usage of plastics.

With kraft surface, the coffee pouch could have a thick and strong feeling as well.

Chapter 4.3.3: Biodegradable Box Bottom Bags With Tin Tie Closing

There are 4 types of closures for flat bottom Pouches: regular ziplock, pocket ziplock, tin tie closing, and heat sealing.

You could choose one of the options according to your promotion purposes.

Chapter 4.4: Unique shaped biodegradable pouch

Flexible packaging pouches are fully customized, not only with pouch type, pouch size, also the pouch shapes. For example, the pouch could be designed with a shape of apple, banana, orange, ball, or a robot.

Almost all pouch types are available to shaped biodegradable packaging bags. They are specially designed for some promotion and branding needs.

With unique shapes, your branded packaging bags will stand out on the shelf among the competitors. All material used provides high barrier. Some snacks will normally be packed in small sachets and then bulk pack by bigger pouches.

Chapter 4.5: 3-Side Seal Biodegradable Pouches

3-side seal bags, also called Flat pouches, are the perfect solution for efficient and economical food and snacks packaging. The simplicity of Ouma biodegradable flat pouches ensures that minimal effort is required to package and seal these bags, giving customers more time and money to distribute to other channels.

Available in clear poly or matt materials, these green packaging pouches provide great packaging alternatives. Various colors and printed patterns are available to suit the needs of any product.

Chapter 4.6: Biodegradable Quad Seal Bags

Biodegradable Quad seal bags are close to box pouch packaging style. These quad seal food bags are getting much popular because the bag looks like a box and we can print the HD graphics on all four sides of the bag. So the bag looks very good due to this.

Quad seal bags comes with all the four side sealed and also the top is sealed. One side of the bag will be kept opened so we can fill the product from the open side and than sealthe bag with heat sealing machine.

These bags can be used to pack products like coffee, tea, fertilizer, pulses, chocolates, dried fruit, nuts, jerky, protein powder etc.

Ouma manufactures biodegradable quad sealed bags with custom materials combination and custom printing possible in Brown kraft paper, white paper, PLA, PBS, NK, NKME film etc.

We can also apply one way degassing valves in quad seal bags for coffee packaging. We can make euro hook, rounded corners, round hanging hole, k seal bottom etc in quad sealed bags.

Chapter 4.7: Biodegradable Vacuum Packaging Bags

Vacuum packaging bags are manufactured by using multilayer films. Vacuum packaging bags can be customized by having the following; euroslot, cut-out handles to ensure comfortable handling. The pouches that are made available for vacuum packaging bags include:

- Three-side seal bags

- Stand up pouches

- Side gusset bags and more

Vacuum pouches can be produced as clear or frosted. Surface printing will be done on the packaging design. Making use of vacuum packaging bags elongates shelf life of goods. Make sure to indicate what size pouch you would want to order, as the size variations range from; 50gr, 75 gr, 100 gr, 150 gr, 250 gr, 500 gr, 1 kg or even more.

The process of Vacuum packaging includes removing surplus air within plastic pouch prior to final sealing. By making use of nitrogen, which is a form of inert gas t helps prevent the crushing of delicate foods.

Chapter 5: Biodegradable Pouch Materials Guide

To keep long lastingness of food taste, flavor and freshness, biodegradable pouches with the capability to long last will be the significant need for the packaging of food and snacks. Coffee bags for the packaging of coffee take a significant part in packaging. Precisely, when these packages reach the market consumers, food or coffee flavor must be fragrant and taste the same as if it is directly exported from the coffee gardens.

Biodegradable food packaging bags from Ouma flex pack are a great promotional packaging tool that could be used as it lures consumers to the shelves hence encouraging purchases. All sustainable packaging bags can be custom printed, as we make use of the latest rotogravure printing techniques, up to eight colors can be used.

Biodegradable Pouches are made with the mixture of two & three distinct layers below:

PHAs (Polyhydroxyalkanoates): are a class of biodegradable plastic naturally produced by various micro-organisms (example: Cuprividus necator). Specific types of PHAs include poly-3-hydroxybutyrate (PHB), polyhydroxyvalerate (PHV) and polyhydroxyhexanoate (PHH). The biosynthesis of PHA is usually driven by depriving organisms of certain nutrients (e.g. lack of macro elements such as phosphorus, nitrogen, or oxygen) and supplying an excess of carbon sources. PHA granules are then recovered by rupturing the micro-organisms.

PLA (Polylactic acid): Polylactic acid is thermoplastic aliphatic polyester synthesized from renewable biomass, typically from fermented plant starch such as from corn , cassava , sugarcane or sugar beet pulp. In 2010, PLA had the second highest consumption volume of any bioplastic of the world. PLA is compostable, but non-biodegradable according to American and European standards because it does not biodegrade outside of artificial composting conditions.

Cellulose-based plastics: Cellulose bioplastics are mainly the cellulose esters, (including cellulose acetate and nitrocellulose) and their derivatives, including celluloid. Cellulose can become thermoplastic when extensively modified. An example of this is cellulose acetate, which is expensive and therefore rarely used for packaging.

Petroleum-based plastics: Petroleum-based plastics are derived from petrochemicals, which are obtained from fossil crude oil, coal or natural gas. The most widely used petroleum-based plastics such as polyethylene terephthalate (PET), polyethylene (PE), polypropylene (PP), and polystyrene (PS) are not biodegradable. However, the following petroleum-based plastics listed are.

PGA (Polyglycolic acid): Polyglycolic acid is a thermoplastic polymer and an aliphatic polyester. PGA is often used in medical applications such as PGA sutures for its biodegradability. The ester linkage in the backbone of polyglycolic acid gives it hydrolytic instability. Thus polyglycolic acid can degrade into its nontoxic monomer, glycolic acid, through hydrolysis. This process can be expedited with esterases. In the body, glycolic acid can enter the tricarboxylic acid cycle, after which can be excreted as water and carbon dioxide.

PBS (Polybutylene succinate) : Polybutylene succinate is a thermoplastic polymer resin that has properties comparable to propylene. It is used in packaging films for food and cosmetics. In the agricultural field, PBS is used as a biodegradable mulching film PBS can be degraded by Amycolatopsis sp. HT-6 and Penicillium sp. strain 14-3. In addition, Microbispora rosea, Excellospora japonica and E. viridilutea have been shown to consume samples of emulsified PBS.

PCL (Polycaprolactone): Polycaprolactone has gained prominence as an implantable biomaterial because the hydrolysis of its ester linkages offers its biodegradable properties. It has been shown that firmicutes and proteobacteria can degrade PCL. Penicillium sp. strain 26-1 can degrade high density PCL; though not as quickly as thermotolerant Aspergillus sp. strain ST-01. Species of clostridium can degrade PCL under anaerobic conditions.

PVA, PVOH {Poly(vinyl alcohol)}: Poly(vinyl alcohol) is one of the few biodegradable vinyl polymers that is soluble in water. Due to its solubility in water (an inexpensive and harmless solvent), PVA has a wide range of applications including food packaging, textiles coating, paper coating, and healthcare products.

PBAT (Polybutylene adipate terephthalate): Polybutylene adipate terephthalate (PBAT) is a biodegradable random copolymer.

NK & NKME: NK is a transparent high barrier heat-sealable compostable film. Based on renewable resources, it’s certified as compostable in both industrial and home composting environments, also suitable for anaerobic digestion. It has the features of Excellent moisture barrier, Excellent barrier to gases and aromas, Heat sealable on both sides, Excellent transparency and gloss, Excellent dead-fold characteristics, Inherent anti-static properties, Resistant to oils and grease. NK is formulated to comply with EU legislation for many room temperature food contact applications. Customers intending to use the film in a food contact application must request the Declaration of Compliance which gives full details.

The only difference between NK & NKME is that NKME has one more feature of UV lights barrier.

Ouma biodegradable eco-friend pouches & bags can be manufactured by various different multi-ply structures, according to different packaging purposes:

- Kraft // PLA

- Kraft // NK // PLA

- PLA // NKME // PLA

- Kraft // NK // PBS

- Kraft // NKME // PBS

- NK // PBS

- Others by requests

The main materials we use for Ouma biodegradable pouches are certificated by FDA. You could get all our materials certificates by just simply sending us an email.

Chapter 6: Biodegradable Pouches Manufacturing Guide

Perfect biodegradable bag packaging will bring you both long shelf life span and fruitful marketing of your brand. It also create a wonderful emotional connection between your products and the consumers.

Ouma flex pack has been devoting ourselves to help achieve your success in the food and snacks market. So we take the food packaging bag quality so important as our lives. We focus on each process during the eco-friend packaging pouch production, ensuring the flexible pouch quality.

Chapter 6.1: Biodegradable Pouch Production Process

1. Order confirmation:

After having your purchase order, we will contact you and confirm each detail via email and telephone. You are welcome to reach us 7*24 by email or phone call whenever you like.

You will have our sales confirmation within 24 hours, including the size, color, add-ons and lastly the purpose. We will specify the requirement or properties you need to be included in your Coffee Bags.

2. Down payment:

We will send you the proforma invoice after you sign and send back the sales confirmation. You are supposed to arrange the down payment according to the PI. Normally, it will be 30% to 50% of the order amount.

We will launch the process upon the receipt of the down payment bank slip.

3. Raw materials preparation:

Our production department will prepare all the plastic films, and add-ons like valves, ziplock, spouts, etc.

If there is printing on the pouches, the printing cylinders will be arranged at the same time. It takes 7-10 days for the preparation of all raw materials and coffee pouch accessaries.

4. Printing:

All printing processes reproduce lines and / or dots that form an image. Printing is the process of manufacturing multiple copies of graphic images. Although most people think of printing as putting ink on paper, printing is not limited to any particular materials or inks. The embossing process uses no ink at all, and all shapes and sizes of metals, wood and plastics are common receives of printed messages.

The following major printing processes are used to reproduce graphic images. Each of these processes is suited for specific applications, such as newspaper, book, packaging bags, or textile printing.

–Relief printing:

The relief printing process includes letterpress printing, flexographic printing, and all other methods of transferring an image from a raised surface.

–Intaglio printing:

Intaglio printing is the reverse of relief printing. An intaglio image is transferred from sunken surface. It’s also known as gravure printing, photogravure printing.

–Screen printing:

Screen printing transfers an image by allowing ink to pass through openings in a stencil that has been applied to a screen mesh.

–Lithography printing:

It’s a relatively new process, dating from around 1798. Offset lithographic printing is the most widely used printing process in the commercial printing industry.

5. Composition:

The advent of composites was a revolutionary shift in packaging.Each single material has its own advantages, disadvantages and characteristics.

For example, metallic materials are brittle and not resistant to corrosion, but have excellent barrier properties; LDPE is chemically resistant, easy to heat seal, and easy to process, but its strength and oxygen barrier properties are poor.

Composite can make up for the shortcomings so that a variety of single-performance materials are combined into a new material with comprehensive performance.

The soul of composite flexible packaging lies in the composite, is the superposition of performance. This is also the technical core of the production of composite flexible packaging.

6. Curing:

After the packaging bag roll films are composited, it could not go for slicing right away. Because it takes 72 hours of curing before it’s available for next process. It’s important to make sure it’s a fully curing, otherwise the composite layers may peel off.

7. Slicing:

The roll-form raw material will be cut by slicing machines to exactly the width needed for a pouch. There will be always big quantity of film rolls, the slicing machine will cut with an accuracy of 0.1mm, and keep the roll in perfect conditions.

A perfect slicing will help to speed up the converting process. Otherwise, it will slow the production speed, and waste the coffee bag raw materials, bringing lots of lots and time and costs.

8. Converting:

Most of the converting job is done by machines. After loading the coffee bag film roll onto the converting machine, it will go through the first part of the machine, folding according to the pouch type, sealing the bottom and both edges, punching holes, adding ziplock, etc.

9. QC (Quality Control):

Product quality is the basis for the long-term development of enterprises. In order to ensure that all goods meet quality standards, we have established a perfect quality control system:

A. IQC: In-Line QC, there will be 3 production engineers keep checking each section on the production line during the whole production. In fact, the machines have auto monitoring functions, but we still arrange QC checking for 100% assurance.

B. FQC: Final QC: at the end of the production line, there is 1 QC checking each bag, and pick out the disqualified one.

C. OQC: Outgoing QC: before packing to export cartons, we arrange outgoing QC to do another 100% quality checking and pick out disqualified items in the case.

10. Packaging:

After the packaging pouches & bags are through the full QC process, they will be packed by bundles, putting into transparent poly bags. Pouches in bundles will be packed into corrugated cardboard cartons.

The packing quantity of each carton could be indicated by clients, according to different sales methods and purposes. In this way, the pouches will be packed by customized cartons specially for this order, instead of standard size. There will be extra cost for custom cartons.

There could be custom printing on cartons and labels as well. This will also cost a small amount from the client, but it will bring great help to the promotion and storage.

Chapter 7: Biodegradable Pouches Product Testing

Besides the quality control during the whole biodegradable packaging bag manufacturing, we will carry on a lot of testing from the arrival of raw materials until the delivery of the pouches. In this way, we can assure that all the food packaging bags we deliver are all qualified, and strictly produced according to the purchase orders.

Chapter 7.1: Testing of raw materials for biodegradable flexible packaging

1.Quality testing of plastic films

Plastic films are one of the most important raw materials for the flexible packaging production. So we take this material testing very seriously. It mainly covers the testing as follows:

- Quality control of film appearance

- Quality control of film width and thickness

- Quality testing of film tensile properties

- Quality control of film surface tension

- Quality testing of the coefficient of film friction

- Film heat sealability testing

- Testing of thickness and adhesion of aluminium coated layer

- Detection of the thermal shrinkage of plastic films

- Testing the puncture resistance of plastic films

- Testing of plastic film transparency and haze

2.Quality testing of flexible packaging paper

The testing to the paper used for packaging pouches and bags include the follows:

- Testing of paper thickness

- Quantitative paper testing

- Detection of paper moisture content

- Paper smoothness test

- Testing the tear resistance of paper

- Testing the tensile strength of paper

- Testing of paper breakage resistance

3.Quality testing of Aluminium foil for flexible packaging

Aluminum foil and aluminum coated foil are both very important high barrier raw materials for flexible packaging, especially food pouches and coffee bags. So the testing is very important and strict.

- Appearance inspection of aluminum foil

- Testing of aluminum foil width and thickness

- Surface cleaniness test of aluminum foil

- Pinhole detection of aluminum foil

4. Quality testing of other packaging bags raw materials

- Printing ink for flexible packaging

- Flexible Packaging Laminated Adhesives

- Ziplock and slider closure for biodegradable bags

Chapter 7.2: Testing of manufacturing processes for biodegradable bags

It’s mainly about the testing of biodegradable pouch gravure printing and packaging bag composition. Print quality can have a huge impact on a customer’s brand image. Flexible packaging lamination can have a significant impact on the user experience.

The testing of printing quality includes the testing of appearance, overprint error, fastness between plastic films and ink, printing color difference, ink glossiness, etc. The testing of composition covers the testing of adhesive spread, glue viscosity control, etc.

Chapter 7.3: Testing of biodegradable bags quality

Testing of flexible packaging pouches and bags is one of the most important part among Quality Control (QC). The testing covers a wide range of subdivisions. Barrier testing of the green packaging bag raw materials: gas permeability & mooisture penetrability testing.

Testing of flexible packaging raw materials physical property:

- Tensile property

- Strength of composite

- Strength of sealing

- Tightness

- Pressure resistance

- Drop performance

Physicochemical and hygienic properties testing:

- Residual solvent

- Odour detetion

Chapter 8: Biodegradable Pouches Storage and Transportation

After the bio-plastic bag production is done, we will proceed with the delivery and shipping arrangement. During the period, the sustainable packaging bags will be stored in our warehouse for a couple of days.

All warehouses are in our plants, so all the cargos will be safe and sound before delivery. In most cases, it takes only 15-25 days to deliver your orders.

We work with professional forwarders for logistics and shipments. They will take care of everything about shipment and send the cargos all over the world according to schedules. We sell and deliver our goods to more than 40 countries in Asia, Europe, North America, South Africa, and Oceania.

We won’t bother the clients about the shipping and transportation by offering considerate service, including the customs clearance and transit on destination ports. The clients will save a lot of time and trouble from the jobs, just waiting for the cargos at their location.

| Loading Ports | Destination | Port of Discharge |

|---|---|---|

| Shenzhen / Guangzhou / HK | USA | Los Angeles / Oakland / New York / Chicago |

| Shenzhen / Guangzhou / HK | Australia | Melbourne / Sydney |

| Shenzhen / Guangzhou / HK | Netherlands | AMSTERDAM / Rotterdam |

| Shenzhen / Guangzhou / HK | Canada | Vancouver / Toronto |

| Shenzhen / Guangzhou / HK | South Africa | Cape Town / Durban |

| Shenzhen / Guangzhou / HK | Europe | Antwerp / BREMEN / HAMBURG / FELIXSTOWE / Barcelona |

Chapter 9: Biodegradable Pouches Frequently Asked Questions (FAQ)

What is Biodegradable?

Simply put, something is “biodegradable” if it can be disintegrated by bacteria, fungi, or some other biological process. If you look at the word itself, the meaning is right there. “Bio” meaning “life,” “degrade” meaning to break down, and “able” of course meaning that it can happen. Biodegradation is basically just the process of nature taking its course and breaking down materials to their component parts. Plastic will break down into carbon dioxide, water, and a few other things.

What is Compostable?

In the packaging world, compostable means something a bit different. Typically, what a packaging company means when they call their product “compostable” is that it can be turned into compost… if entered into an industrial composting facility. This is an important distinction. Compostable products do not always biodegrade naturally in a landfill. They have to be placed in the right kind of conditions, conditions that are often only found in industrial compost facilities. Compostable products will take much longer to break down if in a landfill, especially an “air locked” landfill where there will be no oxygen.

Compostable products are great for the environment, but it is important to make sure that your business has the proper waste management processes in place. Make sure that your compostable waste is going to a compost facility.

What’s the difference between Compostable & Biodegradable?

The primary difference between compostable and biodegradable is that compostable products require a specific setting in order to break down, whereas biodegradable products break down naturally. Typically composting is a faster process, but only under the right conditions. Both of these kinds of products are better for the environment than plastic products that can take hundreds of years to disintegrate.

All compostable items are biodegradable, but not all biodegradable products are compostable. A notable difference between the two is that biodegradable products break down into a few natural elements, while compostable products leave behind a single organic material called humus.

The term biodegradable is assigned to natural products that can be disintegrated into natural elements (such as carbon dioxide and water vapor) with the help of fungi, bacteria, and other biological processes. Almost everything is biodegradable, even some plastic, though it may take these products centuries to break down entirely.

Composting, in comparison, is the process of recycling organic waste for reuse. When carried out correctly, goods can be broken down in just a few months. The result is a healthy soil containing humus, which has a nutrient-rich makeup. The composting process allows organic carbon to return to the earth and reduces methane emissions (aka greenhouse gases).

What’s Biodegradable Pouch?

A biodegradable pouch is the eco-friend flexible packaging bag made of the materials that it can be broken down naturally by microorganisms such as bacteria, fungi under certain conditions (temperature, humidity, etc.).

biodegradable plastics decompose much faster than their traditional counterparts which may take hundreds of years to break down. This pouch is widely used for the Fast-Moving-Consumer Goods Industries.

What are the Benefits of Biodegradable Pouch?

There are many benefits when choosing biodegradable pouches, here is the list of the top seven reasons why we should choose biodegradable packaging products for your business.

1. Reduction In Carbon Emissions

Polystar’s unique biodegradable material is made from PLA bioplastic. As this is plant-based, the manufacturing process produces far fewer carbon emissions than traditional plastic. While traditional plastic releases four tons of emissions, biodegradable plastics emit only 0.8 tons of carbon – a 500% reduction!

2. Waste Reduction

Currently, the UK generates over 30 million tonnes of household waste every year, approximately 35% of which is garden and kitchen waste. As biodegradable plastics break down over time, this means there is a large reduction in the volume of waste being created which means less waste ending up in landfill. With less wastage taking up space in landfills, the outcome is less overall waste to manage. Saving land for other purposes and preserving the beauty of our planet.

3. Repurposing & Recycling

The oils that come from plants make bioplastics far superior materials compared to traditional plastic types. The oils make the surface of bioplastics more malleable and less brittle so that it’s easier to form new shapes and textures.

They are just as moldable as traditional plastics and can be turned into various appealing ways to suit your requirements. In addition to this, they can also be recycled and repurposed multiple times in their life cycle.

Compare this to some non-biodegradable plastics, they are not safe for repurposing because some materials can leak toxic, dangerous chemicals that may leak after the first use. Since biodegradable bags and packaging come from natural materials found in nature, there are no dangerous chemicals or toxins in these items.

4. Reduced Pollution

As biodegradable products break down naturally, they eventually decompose and are consumed by soil and other natural components. This natural process means no forced chemical reaction needs to take place to kickstart the process and less pollution will happen as a result.

Given that they take a lot less time to decompose than traditional plastics, they are easy to recycle, that’s too without releasing toxic elements.

5. Non-Toxic

Biodegradable bags are made from natural materials which means that they are safer for users.

Traditional plastics are made with harmful by-products and chemicals which are a threat to the environment and life as well. They are likely to emit these harmful substances during the breakdown process. What’s more, the plastic used for most standard water bottles, PET, can attract harmful bacteria or even leak chemicals.

But this is not a case with biodegradable plastic, further supporting the case for biodegradable plastics. They are safe and don’t release toxins during their breakdown process. They are absorbed by the soil.

6. Less Petroleum

Biodegradable plastics also minimises the use of petroleum supplies. Traditional plastic is manufactured by oil molecules being heated and treated to convert into polymers.

Nearly 2.7 per cent of a country’s petroleum is used in the traditional plastic manufacturing processes.

Biodegradable plastics, on the other hand, are made using natural materials such as sugar cane, corn, orange peels, starch, and plants. This process requires far less energy and usually does not involve the burning of fossil fuels.

Therefore, this means that the amount of biodegradable plastics that can be manufactured is much higher while simultaneously using far less energy. So, as well as using less precious resources, there is less pollution being produced. By reducing the production of traditional plastics and making more biodegradable plastics instead, we can reallocate oil resources to other causes like heating and transport.

7. Brand Friendly

Another benefit of biodegradable bags is the positive effect it can have for your brand. Major corporations such as Coca-Cola are using bioplastic products due to its sustainable reputation. Choosing greener options can have a positive impact on your brand alongside helping the environment.

How much does it cost to make a biodegradable bag?

According to the California Grocers Association, which opposed San Francisco’s recently-implemented ban of plastic grocery bags, standard plastic bags cost about 2 cents (1 euro cent), a paper bag 5 to 8 cents, and a biodegradable bag can cost roughly 15 cents.

The above is just a rough idea. To have the real and best quotation, the full details of pouch dimensions, materials requests, printing, inquiry quantity are necessary.

Can I put biodegradable in compost?

Items simply listed as biodegradable cannot be placed in your compost container, nor should biodegradable bags be used to set out your extra organic material.

What’s the difference between different types of plastic?

1. Biodegradable plastics

Biodegradable plastics are designed to biodegrade in a specific medium (water, soil, compost) under certain conditions and in varying periods of time.

2. Industrially compostable plastics

Industrially compostable plastics are designed to biodegrade in the conditions of an industrial composting plant or an industrial anaerobic digestion plant with a subsequent composting step.

3. Home compostable plastics

Home compostable plastics are designed to biodegrade in the conditions of a well-managed home composter at lower temperatures than in industrial composting plants. Most of them also biodegrade in industrial composting plants.

4. Bio-based plastics

Bio-based plastics are fully or partly made from biological raw materials as opposed to the fossil raw material (oil) used in conventional plastics.

5. Non-biodegradable plastics

Non-biodegradable plastics last for long periods of time. They can disintegrate into smaller pieces, forming microplastics, and accumulate in the environment.

6. Oxo-degradable plastics

Oxo-degradable plastics include additives that, through oxidation, lead to their fragmentation into microplastics or chemical decomposition.

Are Biodegradable Stand up Pouch Recyclable?

The eco-friendly nature of the pouch increases the recycling capacity of the pouch.Also, the renewable materials contained in the pouch guarantees its recyclability.The recycling capacity of the pouch makes it eco-friendly and a cost-effective choice.There are several ways to recycle the pouch.It’s up to you to decide on the process of recycling the pouch.

Can you Print on Biodegradable Stand Up Pouches?

A pouch should be able to reflect your brand and product information.This is important in distinguishing your product from that of your competitors.Your products should be instantly recognizable and also aesthetically distinctive hence it’s important to use a pouch that can be printed.

The materials used in the manufacturing of Compostable pouches ensure that pouches are printable.You can request for printing to be done on your pouch to reflect your product and company branding.The printability of the pouch makes it aesthetically appealing.It also increases products and brand marketing.

Are there Biodegradable Stand Up Pouches with Zippers?

You can opt for Compostable pouch with zippers, which is a flexible and efficient packaging choice.The zippers ensure that the content of the pouch is kept safe and healthy.

The zippers can be resealable, which allows you to open and close the pouch.The zip-lock closure is perfect for products with long shelf life.Zip lock pouches are long-lasting, and it is commonly recommended for the packaging of food items containing fatty acids.

Are Biodegradable Stand up Pouches Safe?

We make Compostable pouches with sustainable and renewable materials.That makes the pouch fit and safe for the packaging various products.This also includes edible products.

The pouch is manufactured in line with FDA guidelines.These pouches will ensure your products remain fresh without losing the natural.The interior of the pouch has a recyclable film that guarantees that the products are not contaminated.

Do Biodegradable Stand Up Pouches have Moisture Barrier Property?

We have designed the pouch to be highly resistant to external factors such as dust, heat, and moisture. You can use the pouch for the packaging of moist products such as oats, candy, snacks, etc. The interior of the pouch has a film that is with the feature of moisture, and oxygen barrier.

Are Biodegradable Stand Up Pouches Freeze Safe?

Biodegradable pouches are one hundred percent freeze safe.If you need to store your products in cold rooms and refrigerators, then the compostable pouch is perfect for you. The pouch is highly resistant to breakage and leakage, which makes it perfect for storing.

Are there Size Limitations for Biodegradable Stand Up Pouch?

Compostable pouch comes in different sizes. You can choose the size range that suits the needs of your products. The size range for the pouch is between 1oz – 5lbs.

You can customize the pouch to come in specific shapes and sizes. With the information in this guide, am sure you can choose high quality and reliable compostable stand up pouch.

Why bioplastics are eco friendly?

In the future, we are likely to see bioplastics which will be more eco-friendly than their conventional fossil fuel equivalents. … Using these plants to produce bioplastics means CO2 is removed from the atmosphere and stored throughout the entire life of the product, and greenhouse gases reduced.

Why are bioplastics so expensive?

Bioplastics are also relatively expensive; PLA can be 20 to 50 percent more costly than comparable materials because of the complex process used to convert corn or sugarcane into the building blocks for PLA.

What is the future of bioplastics?

In the future, the goal is to use residual materials and waste streams for its production as well. Bioplastics have various pros – they are made from non-depletable, renewable resources and are carbon neutral – as well as cons.

Is plant based plastic biodegradable?

Plant-based plastic is a type of bioplastic that is created from agricultural scraps, often from corn, sugarcane, wheat or food waste. … This means the resulting plastic could still be non-biodegradable and be made from up to 80% fossil fuels!

What is Kraft Biodegradable Stand up Pouches?

Kraft biodegradable stand up pouch is a widely used pouch that serves several functions and purposes.It comprises a combination of renewable materials such as wood, cotton, starch, and other materials.

You can use Kraft pouch for the packaging of both edible and non-edible products.The surface of the pouch can be customized and printed to reflect products and brand information.You can add a number of several features to Kraft pouch to configure it to match your specific needs.

Chapter 10: Biodegradable Pouches Packing, Filling, and Sealing

Food freshness and shelf lifespan will be influenced by the process of packing, filling and sealing. Premium biodegradable bags, experienced staff, and suitable equipments are all the important issues during the packaging.

10.1: Packing and Filling

In the food and snack packaging industry, two types of form fill and seal machines are popular and widely used: the horizontal form fill and seal machine (HFFS), and the vertical form fill (VFFS) and seal machine. As you can imagine, their most striking difference is how the products these machines package are dispensed. But beyond the basic structure of the machines, there are a few differences that define the machines and make one or the other a better choice for every company out there, and even every product out there.

*Horizontal form fill and seal machine (HFFS):

Horizontal form-fill- seal (HFFS) machine brings you flexibility combined with rapid change-overs for your production needs, whether your requirements are side sealed pouches or stand-up pouches with or without a zipper, dry products or liquids.

It provides easy operator access and servo assisted recipe driven changeovers with a performance of up to 100 cycles per minute. Standard features include full servo control with HMI interface, operator side loading of film and zipper, up to four standard fill locations, top seal pre-heat, heat, cooling and servo pick-off with empty pouch reject.

*Vertical form fill and seal machine (VFFS):

Vertical Form Fill and Seal machines provide the speed and accuracy required to vertically fill and seal bags with a variety of products to help our customers meet their packaging demands.

Normally it provides a complete vertical filling solution capable of handling any product that requires laminate film structures and polyethylene films and a variety of bag styles including gusset bags, pillow bags, doy-style stand-up bags, flat bottom bags as well as a variety of hole punches and tear notches.

10.2: Biodegradable bags sealing ways

There are 3 kinds of bags & pouches sealing when packing the food and snacks:

*Hot sealing:

This is a sealing based on electric resistance. It’s with easy engineering, simple maintenance.

*Ultra Sonic sealing:

It’s based on ultra-sound frequency. This sealing will make hermetic seals, regardless of seal area contamination.

*Induction Seal sealing:

This sealing is based on electromagnetic resistance. It seals and cools at the same step, enabling packaging for a circular economy.

Chapter 11: OUMA Biodegradable and Compostable Pouches

Ouma flex pack has been in the industry for more than 20 years. We are one of the most professional manufacturers and biodegradable bag converters in China. Ouma biodegradable bags & pouches cover a wide range of pouch types: stand up doypacks, side gusset bags, flat pouch for drip bag coffee, spout pouches for liquid coffee, vacuum pouches, vented pouches, etc.

Our compostable and biodegradable bags are fully customized, ranging from 2 oz to 25 lb. Our innovative sustainable green packaging pouches help you succeed in your local markets. We have set up 3 fully-owned plants, taking control of most processes to produce eco-friend food bags. We have built up a triple-100% inspection working systems, assuring that only qualified bags and pouches will be delivered.

With us, your business is safe! Your money is safe!

We offer a lowest MOQ request among China vendors, helping to lower the risks and costs when the client wants to start a new project and make a trial shoot.

We are always there when you need any helps from us, 7*24. You can reach us easily, with email, cell phone, telephone call, whatsApp, Wechat, etc.

SUMMARY

Coffee packaging only costs you serval percent of the final products. But it’s the first thing the consumers see, touch and feel. It could bring big influence on their decision of purchasing.

With premium, strong, eye-catching packaging, it will upgrade your products, standing out from other competitors. We could not bring you success, but we could help you achieve larger success. That’s why and how a reliable and qualified partner should do for you.